China Reflected Glass

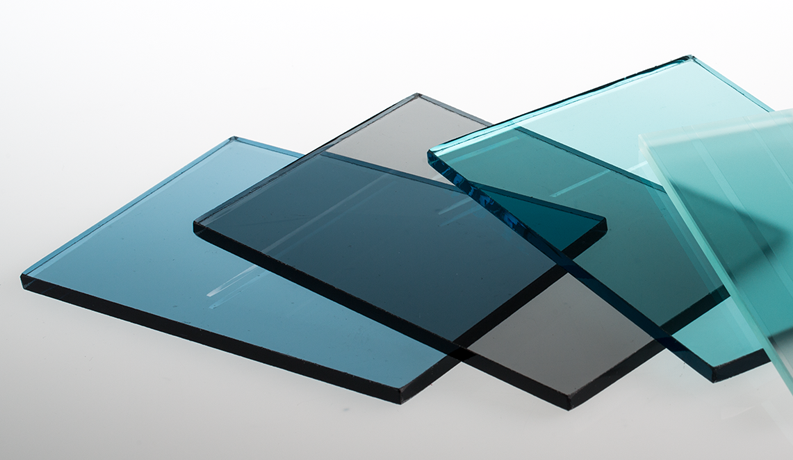

Reflected glass is a distinctive type of glass that possesses unique optical properties, primarily designed to enhance decorative as well as functional applications. Unlike traditional glass, which primarily allows light to pass through, reflected glass has a special coating that reflects a significant amount of light, rendering it both aesthetically appealing and energy-efficient. This reflective quality is achieved through a meticulous manufacturing process that involves the application of metallic coatings to the glass surface, allowing it to exhibit varied visual characteristics based on angle and light conditions.

Reflected glass is a distinctive type of glass that possesses unique optical properties, primarily designed to enhance decorative as well as functional applications. Unlike traditional glass, which primarily allows light to pass through, reflected glass has a special coating that reflects a significant amount of light, rendering it both aesthetically appealing and energy-efficient. This reflective quality is achieved through a meticulous manufacturing process that involves the application of metallic coatings to the glass surface, allowing it to exhibit varied visual characteristics based on angle and light conditions.

The composition of reflected glass typically includes silica, soda, and lime, similar to conventional glass. However, the refining process introduces a variety of metallic oxides, enabling it to reflect and refract light more effectively. This unique manufacturing technique differentiates reflected glass from its traditional counterparts, making it suitable for various applications, such as architectural designs, interior decoration, and automotive glass. Additionally, reflected glass is now extensively used in solar energy technologies, assisting in energy conservation by reducing heat gain in buildings.

Historically, China has played a pivotal role in the development of reflected glass. Its roots can be traced back to ancient times when artisans began exploring advanced glass-making techniques. Over the years, the craft evolved, culminating in the production of reflected glass that is both functional and artistic. Today, reflected glass is esteemed not only for its practical applications but also for its rich craftsmanship heritage, showcasing the skills and artistry of Chinese glassmakers. The evolution of reflected glass in China serves as a testament to the interplay between innovation and tradition, resulting in a remarkable material that caters to modern needs while honoring its historical significance.

CHINA Reflected Glass

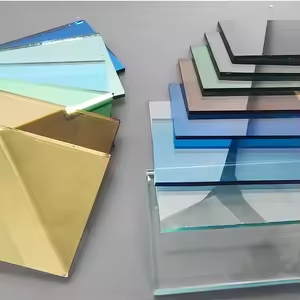

China reflected glass has carved a niche in various sectors, showcasing its versatility across architecture, automotive, and interior design. This sophisticated material not only enhances visual aesthetics but also contributes significantly to energy efficiency and functional benefits, making it a favored choice in modern design practices.

In the architectural realm, reflected glass is often utilized for façade cladding, allowing buildings to harmonize with their environmental surroundings while providing a striking visual impact. An exemplary application can be seen in the design of the International Commerce Centre in Hong Kong, where expansive glass panels showcase reflections of the sky and cityscape, thereby elevating the overall aesthetic appeal. Moreover, these reflective surfaces can help in controlling solar heat gain, thus enhancing energy efficiency by reducing the need for artificial climate control measures.

The automotive industry also employs reflected glass in the production of windshields and windows, where reduced glare and improved visibility enhance safety. For instance, many luxury car manufacturers feature tinted reflected glass that not only provides a sleek appearance but also minimizes heat buildup inside vehicles, contributing to passenger comfort. Notably, advancements in technology have led to the development of smart glass, which can adjust its reflective properties according to environmental changes, thus catering to both aesthetic and functional needs.

Interior design has embraced reflected glass for applications ranging from decorative partitions to tabletops. The use of reflective materials can create an illusion of spaciousness in smaller areas, while also adding layers of sophistication and modernity. For example, high-end restaurants often utilize mirrored surfaces to enhance ambiance and sophistication, making spaces feel more luxurious while reflecting ambient light throughout the environment.

Through these diverse applications, China reflected glass continues to demonstrate its ability to enhance aesthetics, improve functionality, and maintain energy efficiency across multiple sectors, reinforcing its position as an essential material in contemporary design.

CHINA Reflected Glass

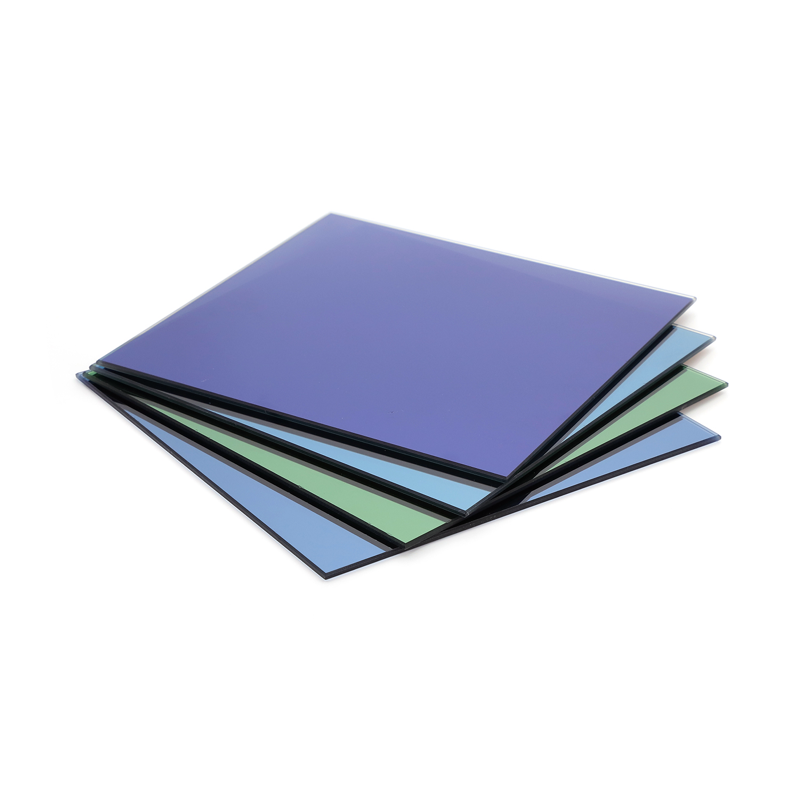

The production of China reflected glass entails a meticulous and technologically sophisticated manufacturing process that begins with the selection of high-quality raw materials. Primary ingredients include silica sand, soda ash, and limestone, which are carefully sourced to meet stringent standards. These materials are combined in specific proportions, forming a batch that will be subsequently melted in a furnace at exceptionally high temperatures, generally exceeding 1,600 degrees Celsius. This process results in a molten glass that can be shaped and refined into various forms.

Once the raw materials have been melted, the molten glass is formed using several techniques, depending on the desired end product. Common methods include blowing, pressing, and casting, all of which enable the creation of glass with complex shapes and properties. After forming, the glass is annealed—a process involving slow cooling within a controlled environment to relieve internal stresses and enhance durability. This step is vital for ensuring the longevity and performance of the reflected glass.

Quality control measures are integral throughout the manufacturing process. Rigorous testing protocols are instituted to assess various physical and optical properties, such as transparency, reflectivity, and thickness. Any deviations from established quality benchmarks are promptly addressed to maintain high standards. Furthermore, advancements in manufacturing technologies have led to innovations in reflective coatings that improve energy efficiency and optical performance. These innovations are coupled with sustainability practices, such as recycling glass scraps back into the production process, thus minimizing waste.

In the rapidly evolving landscape of glass manufacturing, the integration of automation and smart technologies is playing a pivotal role. Automated systems for monitoring production parameters and ensuring consistent quality are increasingly being adopted. This not only enhances efficiency but also aligns with global sustainability goals by reducing energy consumption. By leveraging these technologies and committing to quality assurance, manufacturers of China reflected glass are able to produce products that meet the highest expectations of performance and environmental responsibility.

CHINA Reflected Glass

The reflected glass industry, particularly in China, faces several challenges that have significant implications for its growth and sustainability. One of the primary concerns is the environmental impact associated with glass production and disposal. Traditional manufacturing processes contribute to substantial carbon emissions and resource depletion, prompting a need for greener alternatives. Industry leaders are increasingly focusing on reducing their ecological footprint by adopting sustainable practices and using eco-friendly materials.

Additionally, the reflected glass market is confronted with intense competition, not only from domestic players but also from international manufacturers. This competition often results in price wars that can compromise quality and innovation. Companies must navigate these pressures while maintaining profitability and exploring new markets. The fluctuations in market demand, influenced by factors such as economic stability and consumer trends, also present a constant challenge for producers. Adapting to these changes and anticipating shifts in consumer preferences are crucial for long-term success.

Looking ahead, several trends are expected to shape the future of the reflected glass industry. One notable advancement is the rise of smart glass technology, which offers functionalities such as light control and energy efficiency. This innovation is likely to attract eco-conscious consumers who prioritize sustainability and advanced features in their purchases. Furthermore, the integration of recyclable materials into glass production is gaining traction, reflecting a broader commitment within the industry to promote environmental stewardship.

As manufacturers embrace sustainable practices and invest in research and development, the reflected glass sector can expect to see significant transformations. These developments are anticipated to enhance consumer preferences, driving a demand for products that exemplify both innovation and environmental responsibility. By addressing current challenges and adapting to future trends, the reflected glass industry can pave the way for a more sustainable and resilient market.