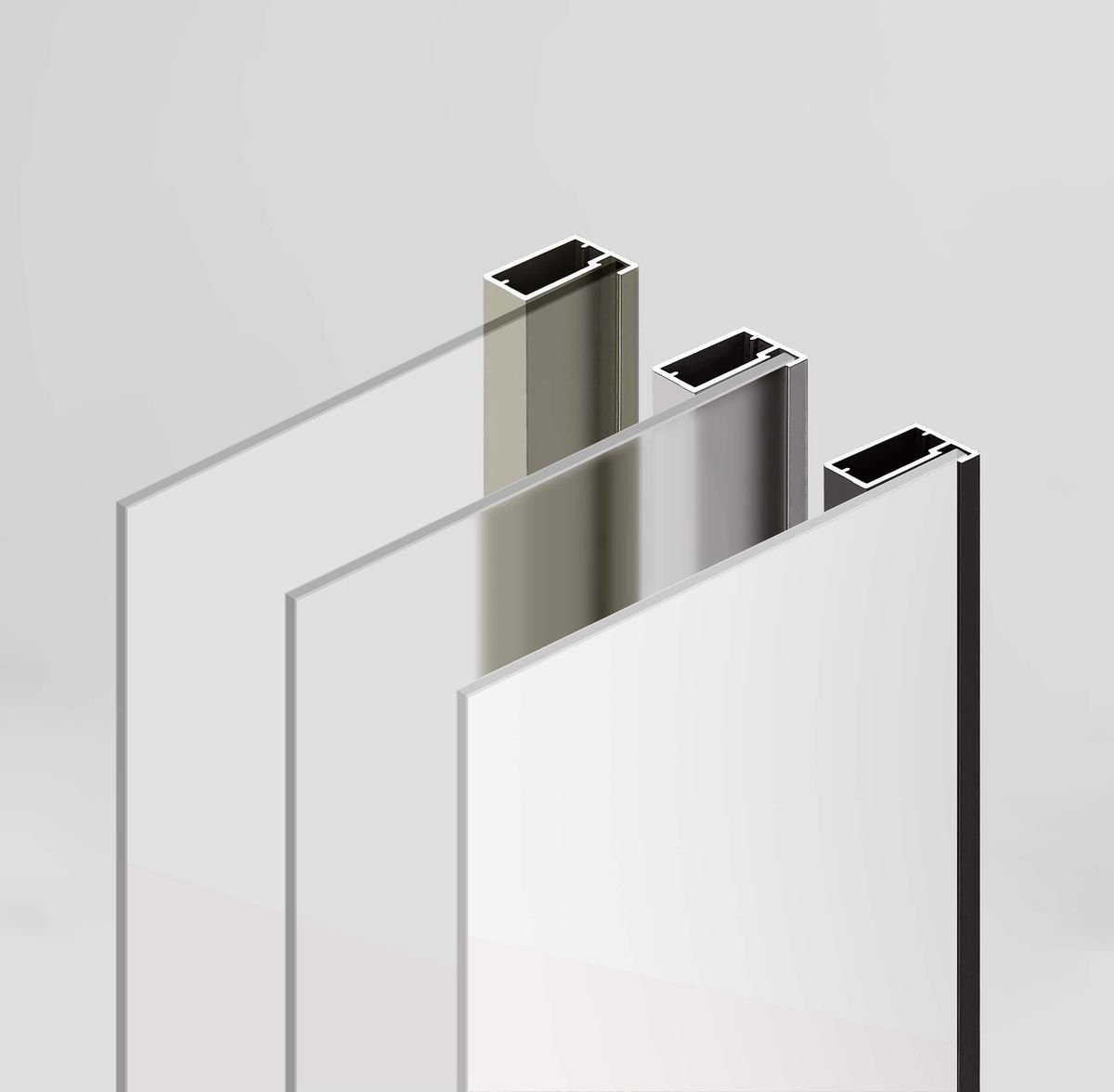

Silver Glass / Mirror

Silver Glass / Mirror : When we think of a mirror, the image that often comes to mind is a smooth, shiny surface reflecting back our appearance. Behind this everyday object lies an ancient yet innovative product: silver glass, also commonly referred to as a silver mirror. From home interiors to automobiles, laboratories, and even in art, silver glass has carved a place of importance.

Silver Glass / Mirror In this detailed article, we will explore what silver glass is, its history, manufacturing process, benefits, uses, and why it remains one of the most admired materials in both functional and decorative fields.

What is Silver Glass?

Silver Glass / Mirror, or a silver mirror, is a type of reflective glass created by coating one side of a flat glass sheet with a thin layer of metallic silver. This coating transforms the otherwise transparent glass into a reflective surface that produces clear and crisp reflections.

Unlike ordinary glass, which allows light to pass through, silver glass reflects light efficiently, making it ideal for use in mirrors. Over the years, silver mirrors have become the industry standard because silver provides superior reflectivity compared to other metals like aluminum or copper.

A Glimpse into History

The use of reflective surfaces dates back thousands of years. Ancient civilizations such as the Egyptians, Greeks, and Romans polished bronze, copper, and obsidian (volcanic glass) to create crude mirrors. While these early mirrors were functional, they lacked the clarity and accuracy of modern versions.

The breakthrough came in the 19th century when German chemist Justus von Liebig discovered a process to deposit a thin layer of metallic silver onto glass. This innovation gave rise to the modern Silver Glass / Mirror, a product that quickly became popular in homes, palaces, and public spaces.

How Silver Glass is Made

The production of silver mirrors involves advanced techniques to ensure quality, durability, and consistency. The key steps in the process are:

- Glass Preparation

A sheet of float glass is selected and cleaned thoroughly. Any dust, oil, or imperfections are removed to ensure the silver layer adheres properly. - Chemical Treatment

The clean glass is treated with chemicals, often tin chloride, to prepare the surface for silver deposition. - Silver Coating

A liquid solution of silver nitrate is sprayed or applied to the glass. Through a reduction process, metallic silver adheres to the prepared surface, forming a thin, reflective layer. - Protective Backing

To safeguard the silver layer, one or more coats of paint are applied. These coatings not only protect against scratches and moisture but also extend the mirror’s lifespan. - Curing and Quality Testing

The coated glass is dried, hardened, and inspected for clarity, reflectivity, and durability.

This precise process results in high-quality silver mirrors with unmatched reflectivity and brilliance.

Characteristics of Silver Glass

Silver mirrors are valued because of their unique qualities:

- High Reflectivity – Silver provides clearer and more natural reflections compared to aluminum mirrors.

- Durability – With proper backing protection, silver glass can last for decades without losing quality.

- Versatility – Available in various shapes, thicknesses, and designs for different applications.

- Clarity – Produces distortion-free reflections with excellent brightness.

- Customizable – Can be cut, beveled, tinted, or etched to suit aesthetic requirements.

Applications of Silver Glass / Mirrors

The versatility of silver mirrors makes them indispensable in both practical and decorative fields. Some major applications include:

1. Residential Interiors

Mirrors are a staple in homes—used in bathrooms, bedrooms, dressing areas, and living rooms. Silver mirrors enhance spaces by reflecting light, making rooms appear larger and brighter.

2. Architectural Design

Architects and interior designers use silver glass creatively in wall panels, ceilings, wardrobes, and furniture to add elegance and depth to modern spaces.

3. Automotive Industry

Rearview and side mirrors in vehicles rely heavily on silvered glass for accurate reflection and safety.

4. Optical Instruments

Scientific tools like microscopes, telescopes, and cameras often incorporate silver mirrors to achieve precise reflection of light.

5. Retail and Commercial Spaces

Shops, showrooms, salons, and gyms use large silver mirrors to enhance ambiance and provide customers with a better experience.

6. Art and Decoration

Silver glass is a favorite medium for decorative wall art, antique-styled frames, and handcrafted mirror designs.

7. Hospitality Industry

Hotels, restaurants, and lounges use mirrors strategically to create a luxurious and spacious environment.

Advantages of Silver Mirrors Over Other Types

While aluminum-coated mirrors are common due to their affordability, silver mirrors are considered superior for several reasons:

- Better Reflection Quality: Silver reflects a higher percentage of visible light, resulting in sharper images.

- Longevity: When protected properly, silver coatings resist corrosion better than aluminum.

- Premium Look: The brilliance of silver mirrors makes them ideal for high-end projects and luxury interiors.

Maintenance and Care

Although silver glass is durable, proper maintenance ensures it remains clear and reflective for years:

- Regular Cleaning – Use a soft cloth and mild glass cleaner. Avoid abrasive materials that may scratch the surface.

- Protection from Moisture – Excessive humidity can damage the backing; therefore, sealed edges and protective coatings are important.

- Handle with Care – Silver mirrors are strong but still vulnerable to cracking or chipping if mishandled.

The Future of Silver Glass

With advancements in nanotechnology and smart materials, the future of silver glass is even more exciting. Researchers are developing smart mirrors that integrate LED displays, touch controls, and anti-fog coatings. Energy-efficient and eco-friendly silvering methods are also being explored to reduce environmental impact.

In luxury architecture and automotive design, silver mirrors will continue to hold their ground, blending functionality with modern aesthetics.

Conclusion

Silver glass, or the silver mirror, is much more than just a household item. It represents a perfect balance of science, art, and everyday utility. From the ancient practice of polishing metals to the modern silver-coating technique, mirrors have evolved into essential elements of our lives.

Whether it’s the reflection we rely on every morning, the decorative touch in a living room, or the precision required in scientific instruments, Silver Glass / Mirror continues to shine as a timeless material.

In an age where design, clarity, and technology matter more than ever, silver mirrors remain a symbol of elegance, innovation, and reliability.